Prestressing is an engineering concept that refers to the application of a load to a structure to counteract loads during its design life.

This method is most associated with concrete but steel, cast iron and masonry structures can also be prestressed.

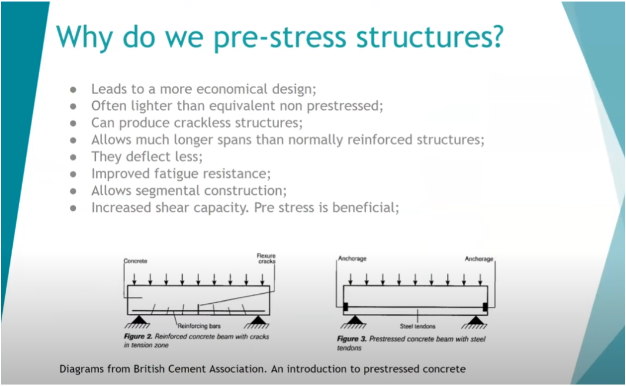

Why Prestress a Structure?

There are several reasons for prestressing a concrete structure, particularly compared to using traditional reinforced concrete.

Economical Design – Prestressing structures can lead to more economical designs particularly in concrete structures, where prestressing can lead to lighter, yet stronger components compared to traditional reinforced concrete.

Crackless Structures – Prestressed structures can be designed to minimise or eliminate micro-cracking that can occur in normal reinforced concrete when the structure undergoes bending. Prestressing counteracts these forces, reducing the chances of cracking.

Longer Spans and Reduced Deflection: Prestressed structures generally allow for longer spans and exhibit less deflection compared to non-prestressed structures. This is a design advantage when constructing bridges and large buildings.

Segmental Construction: Prestressing allows for segmental construction on large-span bridges and other complex structures. Large, heavy components can be manufactured in factories to be transported and assembled on-site.

Increased Fatigue Resistance: The process of prestressing increases the fatigue resistance of the structure, potentially increasing the structures lifespan.

Enhanced Shear Capacity: The application of a compressive force via prestressing significantly increases the shear capacity of concrete. This additional strength increases shear capacity and prevents shear failure.

Pre-tensioned vs Post-Tensioned Concrete

When using prestressing concrete, this stress can be applied to the steel tendons before the concrete is placed (pre-tensioned), or after the concrete has reached design strength (post-tensioned).

Pre-Tensioned (prestressed) Concrete

Pre-tensioned concrete elements are precast off-site and then transported to the construction site. This, however, has historically limited the size of pre-tensioned elements due to restrictions in lifting and transportation abilities.

Common examples of pre-tensioned concrete elements include bridge beams, slabs, lintels, and water tanks.

Post-Tensioned Concrete

Post-tensioned structural elements are cast in situ, making them suitable for larger scale projects, such as long-span bridges or in-situ slabs.

The adaptability to onsite conditions of post-tensioned concrete and the ability to create longer spans and complex structures are key factors to the use of post-tensioned concrete, although there are additional considerations required when demolishing such structures.

Hazard of demolishing prestressed structures

There are a number of potential hazards to consider when demolishing prestressed structures

Damage to Structure During Investigation: If the prestressed nature of a structure is not identified during the investigation phase, it can lead to accidental damage if incorrect coring or cutting releases tendons or damages them, leading to structural issues.

Stress Reversal: Altering the support conditions of a prestressed structure, such as during lifting or moving parts of the structure, can lead to stress reversal. This can cause failure if not properly analysed and mitigated.

Release of Non-Grouted Tendons: In structures where tendons are not grouted, there is a risk of tendons releasing if cut or disturbed. This can lead to the tendons ejecting from the structure, posing a serious hazard.

Loss of Shear Capacity: Cutting tendons can affect the shear capacity near supports in a structure, potentially leading to failures.

Read more about the hazards of demolishing post-tensioned structures